Welcome to GuangDong Malex Machinery Technology Co.,Ltd.

Apr 20,2025

Understanding the Cost-Effectiveness of 3 Layers Bubble Film Machines: A Comprehensive Guide

Understanding the Cost-Effectiveness of 3 Layers Bubble Film Machines

Table of Contents

- 1. Introduction to 3 Layers Bubble Film Machines

- 2. How 3 Layers Bubble Film Machines Work

- 3. Advantages of 3 Layers Bubble Film Machines

- 4. Cost-Effectiveness Analysis

- 5. Applications of 3 Layers Bubble Film

- 6. Environmental Impact of Bubble Film Production

- 7. Buying Guide for 3 Layers Bubble Film Machines

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to 3 Layers Bubble Film Machines

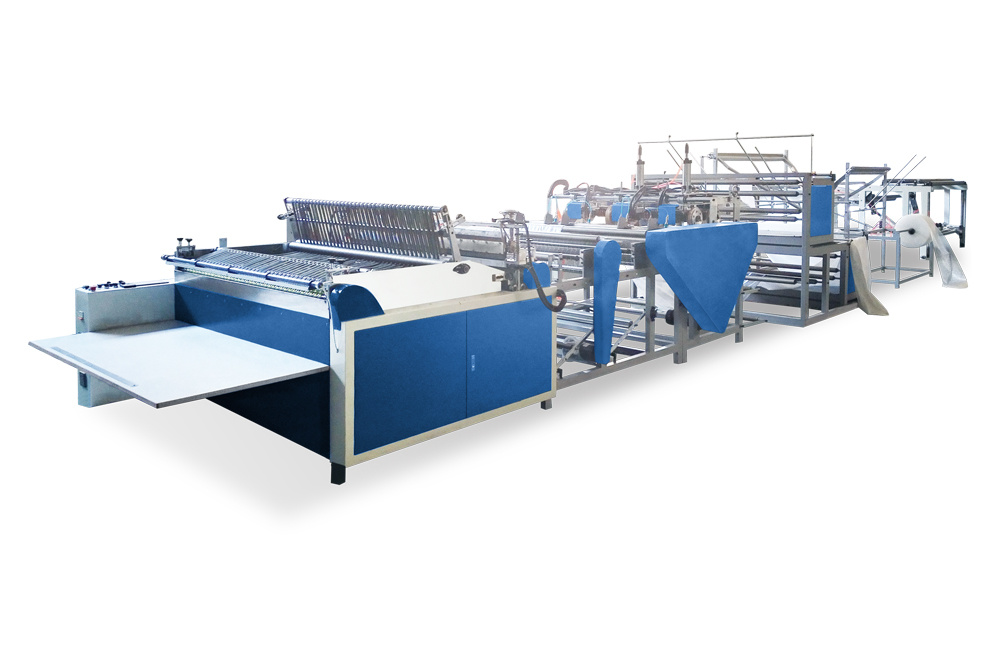

In the realm of packaging and printing, **3 layers bubble film machines** have emerged as a revolutionary solution. These machines are designed to produce bubble film with three layers of material, enhancing strength, cushioning, and insulation. Understanding their cost-effectiveness can help businesses optimize their packaging solutions, leading to greater efficiency and savings.

2. How 3 Layers Bubble Film Machines Work

These machines operate through a sophisticated process that involves the simultaneous extrusion of three layers. The outer layers serve to provide durability and resistance, while the inner layer typically contains air bubbles that offer cushioning. This three-layer configuration is achieved using advanced technology that ensures consistent quality and thickness throughout the production process.

Key Components of 3 Layers Bubble Film Machines

- **Extruders:** Responsible for melting and shaping the plastic material.

- **Die Head:** Creates the specific shape of the bubble film.

- **Cooling System:** Ensures that the film maintains its form and strength.

- **Winding Unit:** Rolls up the finished bubble film for easy storage and transport.

3. Advantages of 3 Layers Bubble Film Machines

Investing in a **3 layers bubble film machine** offers several advantages.

Enhanced Protection for Products

The triple-layer construction provides superior protection against impact, moisture, and temperature fluctuations, making it ideal for sensitive items.

Versatility in Applications

From packaging electronics to fragile glassware, the adaptability of bubble film makes it suitable for a wide range of products.

Improved Production Efficiency

These machines enable high-speed production, allowing manufacturers to meet growing demands without compromising quality.

4. Cost-Effectiveness Analysis

Understanding the cost-effectiveness of these machines involves evaluating several key factors:

4.1 Material Savings

One of the primary reasons businesses invest in 3 layers bubble film machines is the significant **material savings** they offer. The use of three layers ensures that less material is wasted during the production process, which translates to lower costs in the long run. Companies can optimize their raw material usage while still delivering high-quality packaging.

4.2 Energy Efficiency

These machines are designed with energy efficiency in mind. The advanced technology used in the production process reduces energy consumption, leading to lower electricity bills. This efficiency not only contributes to cost savings but also aligns with environmentally sustainable practices.

4.3 Reduced Labor Costs

By automating the production of bubble film, companies can reduce the number of workers needed for packaging processes. This **reduction in labor costs** allows businesses to allocate resources more effectively and focus on other critical areas of operation.

5. Applications of 3 Layers Bubble Film

3 layers bubble film has a variety of applications across numerous industries.

Electronics Packaging

The cushioning properties of bubble film make it ideal for packaging electronic components, ensuring they arrive safely without damage.

Fragile Goods Protection

Glassware, ceramics, and other fragile items benefit from the protective qualities of bubble film, making it a preferred choice for retailers and wholesalers.

Shipping and Logistics

In shipping, bubble film provides an extra layer of protection, reducing the likelihood of breakage during transit.

6. Environmental Impact of Bubble Film Production

In today’s eco-conscious world, the environmental impact of packaging materials is under scrutiny. 3 layers bubble film machines can contribute positively in several ways:

Recyclability

Many bubble films are made from recyclable materials, and manufacturers are increasingly adopting sustainable practices in their production processes.

Waste Reduction

With better material efficiency, these machines help in minimizing waste, contributing to a more sustainable packaging solution.

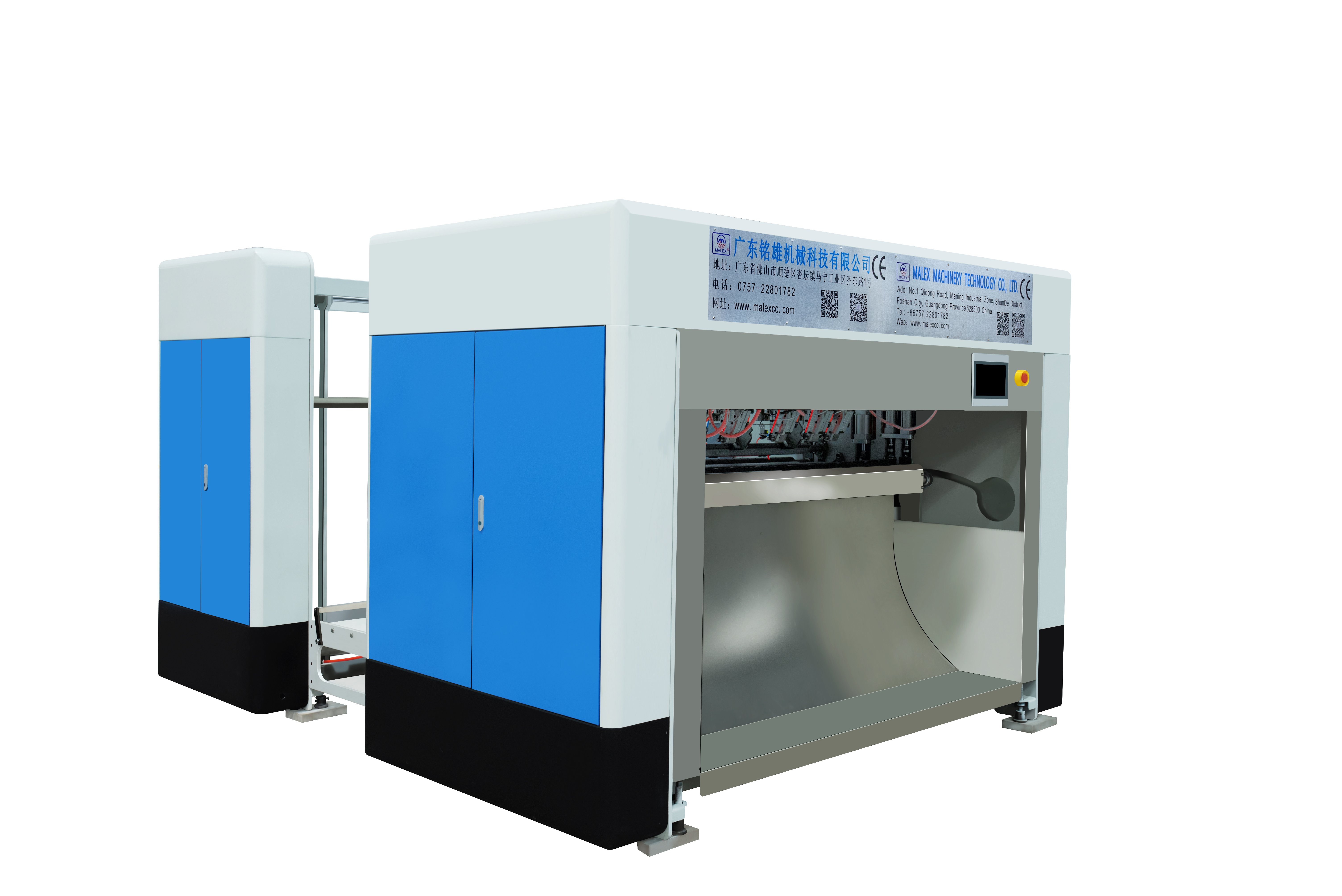

7. Buying Guide for 3 Layers Bubble Film Machines

When considering the purchase of a 3 layers bubble film machine, there are several factors to keep in mind:

Assess Your Production Needs

Evaluate your current and projected production volumes to determine the machine specifications required.

Consider the Technology

Look for machines that incorporate the latest technology for improved efficiency and quality control.

Evaluate Supplier Reputation

Choose reputable suppliers with a proven track record in the industry to ensure reliability and support.

8. Frequently Asked Questions

1. What is a 3 layers bubble film machine?

A 3 layers bubble film machine is a specialized piece of equipment designed to produce bubble film consisting of three layers of material for enhanced strength and protection.

2. How does a 3 layers bubble film machine improve cost-effectiveness?

These machines are cost-effective due to material savings, energy efficiency, and reduced labor costs, leading to significant long-term savings.

3. What industries benefit from using bubble film?

Industries such as electronics, logistics, and retail packaging significantly benefit from using bubble film for protecting fragile and sensitive items.

4. Can bubble film be recycled?

Yes, many bubble films are made from recyclable materials, and efforts are being made to increase the recyclability of these products.

5. What should I consider when purchasing a 3 layers bubble film machine?

Consider your production needs, the technology used in the machine, and the reputation of the supplier to ensure you make a sound investment.

9. Conclusion

In conclusion, investing in a **3 layers bubble film machine** can greatly enhance the efficiency and cost-effectiveness of packaging operations. With benefits ranging from material savings to energy efficiency and reduced labor costs, these machines present a compelling case for businesses looking to streamline their packaging processes. As industries continue to evolve, the demand for versatile and reliable packaging solutions will only grow, making the understanding and implementation of advanced machinery like 3 layers bubble film machines crucial for future success. By prioritizing sustainability and efficiency, companies can position themselves as leaders in the packaging industry.

Related News