Welcome to GuangDong Malex Machinery Technology Co.,Ltd.

Apr 17,2025

Understanding the Benefits and Functionality of 3 Layers Bubble Film Machines

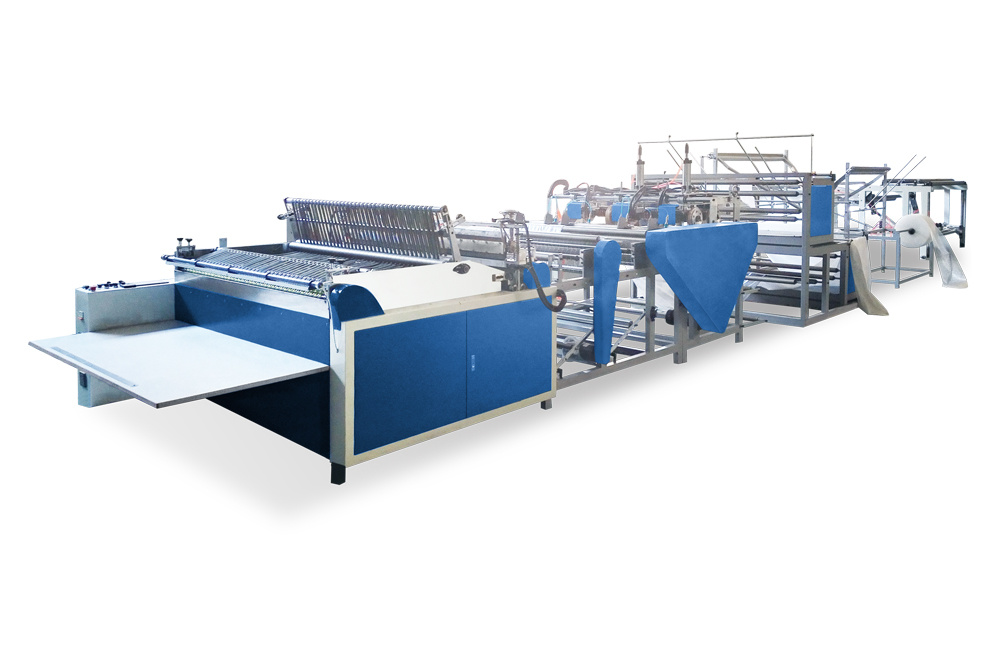

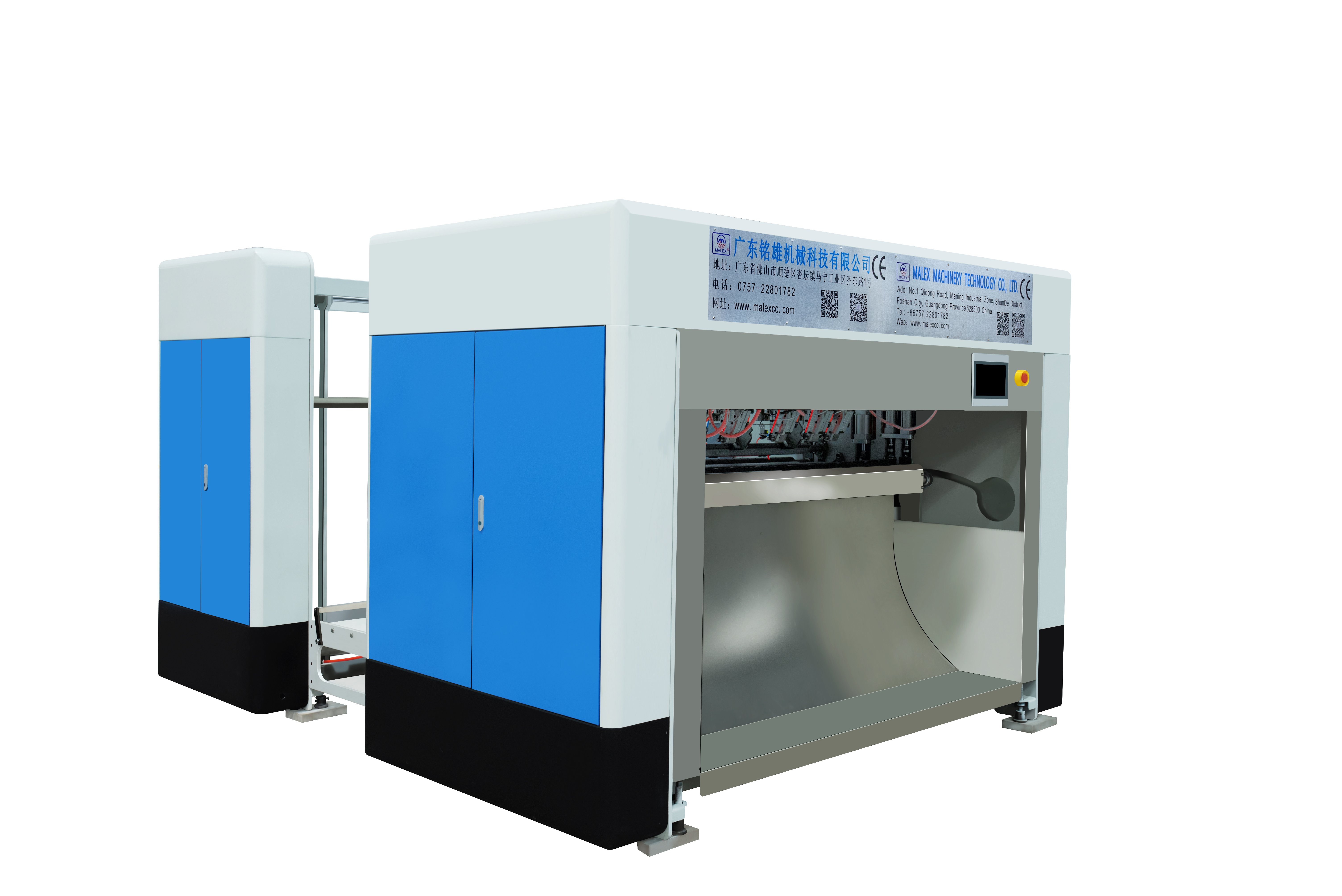

When it comes to modern packaging solutions, the 3 layers bubble film machine stands out as a significant advancement in the field of protective packaging materials. These machines are designed to produce multi-layered bubble film, which is essential for ensuring that products are safely cushioned during transit. Understanding the mechanics, benefits, and applications of 3 layers bubble film machines can greatly enhance your packaging operations.

The primary function of a 3 layers bubble film machine is to create bubble film with three distinct layers, which can improve the overall strength and cushioning properties of the film. The outer layers typically provide durability and tear resistance, while the inner layer contains air bubbles that serve as shock absorbers. This construction not only enhances the protective qualities of the bubble film but also reduces the overall weight, making it cost-effective for shipping and handling purposes.

One of the main advantages of using a 3 layers bubble film machine is its efficiency in production. These machines are capable of high-speed operation, allowing manufacturers to produce large quantities of bubble film in a short amount of time. This efficiency is crucial for businesses that require a constant supply of packaging materials to keep up with demand. Moreover, the multilayer technology ensures that the film maintains its integrity and performance, even under varying environmental conditions.

In addition to speed and efficiency, 3 layers bubble film machines offer versatility in customization. The ability to adjust the thickness, size, and bubble dimensions allows manufacturers to tailor the bubble film to specific product requirements. This adaptability is particularly beneficial for industries with diverse packaging needs, as it ensures that products, regardless of shape or size, are adequately protected.

Furthermore, utilizing a 3 layers bubble film machine contributes to sustainability efforts in the packaging industry. Many of these machines are designed to produce recyclable materials, thereby reducing waste. Companies that prioritize environmentally friendly practices can enhance their reputation and appeal to a growing customer base that values sustainability.

In summary, the 3 layers bubble film machine plays a vital role in modern packaging solutions. By producing high-quality, durable, and customizable bubble film, these machines not only protect products during transit but also improve operational efficiency and sustainability. For businesses looking to enhance their packaging processes, investing in a 3 layers bubble film machine could lead to significant benefits. Understanding the features and advantages of these machines will empower companies to make informed decisions that align with their packaging needs and goals.

The primary function of a 3 layers bubble film machine is to create bubble film with three distinct layers, which can improve the overall strength and cushioning properties of the film. The outer layers typically provide durability and tear resistance, while the inner layer contains air bubbles that serve as shock absorbers. This construction not only enhances the protective qualities of the bubble film but also reduces the overall weight, making it cost-effective for shipping and handling purposes.

One of the main advantages of using a 3 layers bubble film machine is its efficiency in production. These machines are capable of high-speed operation, allowing manufacturers to produce large quantities of bubble film in a short amount of time. This efficiency is crucial for businesses that require a constant supply of packaging materials to keep up with demand. Moreover, the multilayer technology ensures that the film maintains its integrity and performance, even under varying environmental conditions.

In addition to speed and efficiency, 3 layers bubble film machines offer versatility in customization. The ability to adjust the thickness, size, and bubble dimensions allows manufacturers to tailor the bubble film to specific product requirements. This adaptability is particularly beneficial for industries with diverse packaging needs, as it ensures that products, regardless of shape or size, are adequately protected.

Furthermore, utilizing a 3 layers bubble film machine contributes to sustainability efforts in the packaging industry. Many of these machines are designed to produce recyclable materials, thereby reducing waste. Companies that prioritize environmentally friendly practices can enhance their reputation and appeal to a growing customer base that values sustainability.

In summary, the 3 layers bubble film machine plays a vital role in modern packaging solutions. By producing high-quality, durable, and customizable bubble film, these machines not only protect products during transit but also improve operational efficiency and sustainability. For businesses looking to enhance their packaging processes, investing in a 3 layers bubble film machine could lead to significant benefits. Understanding the features and advantages of these machines will empower companies to make informed decisions that align with their packaging needs and goals.

Related News