Welcome to GuangDong Malex Machinery Technology Co.,Ltd.

Apr 23,2025

Unlocking Efficiency: The Benefits of 3 Layers Bubble Film Machines in Packaging

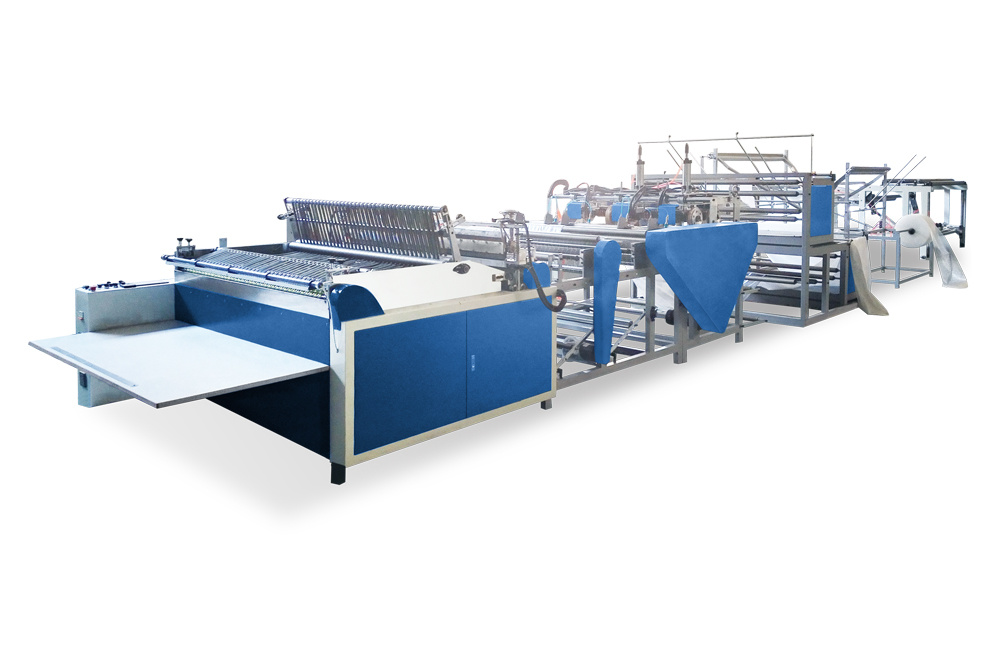

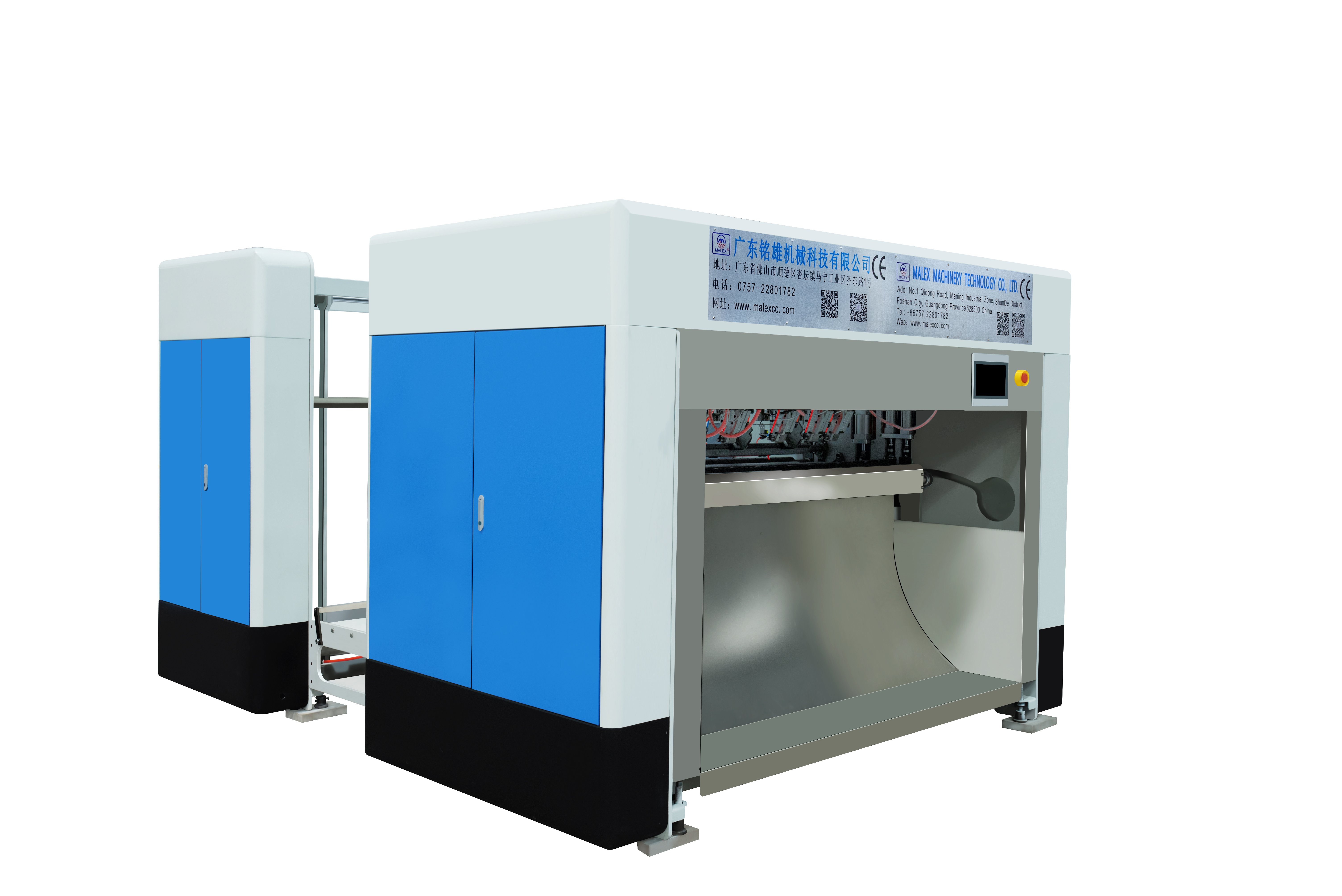

The 3 layers bubble film machine represents a significant advancement in the realm of packaging technology, particularly for businesses involved in composite material packaging. This machine specifically combines three layers to create a unique bubble film that offers excellent cushioning and protection for a wide array of products. Understanding how this technology works and its benefits can greatly enhance your packaging efficiency and effectiveness.

One of the primary advantages of a 3 layers bubble film machine is its ability to produce a stronger and more durable film compared to traditional single-layer options. The three-layer structure not only increases the thickness and resilience of the bubble film but also enhances its ability to absorb shocks during transit. This is particularly crucial for industries where product integrity is paramount, such as electronics, fragile items, and other sensitive materials.

Additionally, the versatility of the 3 layers bubble film machine allows manufacturers to customize the film according to specific requirements. For example, the outer layers can be designed to provide different levels of protection, while the inner layer can be optimized for cushioning performance. This customization enables businesses to tailor their packaging solutions to meet the unique needs of their products, ultimately leading to increased customer satisfaction.

In terms of cost-effectiveness, the 3 layers bubble film machine can significantly reduce material usage without compromising protection. By optimizing the design of the bubble film, businesses can use fewer materials while still ensuring that products remain secure during shipping and handling. This reduction in material waste not only lowers packaging costs but also contributes to more sustainable practices, which are increasingly important in today's environmentally conscious market.

Furthermore, the production speed of a 3 layers bubble film machine is often superior to that of traditional packaging equipment. The ability to produce large quantities of bubble film in a shorter time frame can help businesses streamline their operations, reduce labor costs, and improve overall efficiency. This increased productivity can free up resources that can be utilized in other areas of the business, such as product development or marketing.

In conclusion, incorporating a 3 layers bubble film machine into your packaging operations can provide numerous benefits, from enhanced product protection to improved efficiency and cost savings. As the demand for high-quality packaging solutions continues to grow, investing in advanced machinery like this can position your business advantageously within the competitive landscape of the packaging industry. By leveraging the unique features of 3 layers bubble film technology, you can ensure that your products reach customers in pristine condition while optimizing your operational processes.

One of the primary advantages of a 3 layers bubble film machine is its ability to produce a stronger and more durable film compared to traditional single-layer options. The three-layer structure not only increases the thickness and resilience of the bubble film but also enhances its ability to absorb shocks during transit. This is particularly crucial for industries where product integrity is paramount, such as electronics, fragile items, and other sensitive materials.

Additionally, the versatility of the 3 layers bubble film machine allows manufacturers to customize the film according to specific requirements. For example, the outer layers can be designed to provide different levels of protection, while the inner layer can be optimized for cushioning performance. This customization enables businesses to tailor their packaging solutions to meet the unique needs of their products, ultimately leading to increased customer satisfaction.

In terms of cost-effectiveness, the 3 layers bubble film machine can significantly reduce material usage without compromising protection. By optimizing the design of the bubble film, businesses can use fewer materials while still ensuring that products remain secure during shipping and handling. This reduction in material waste not only lowers packaging costs but also contributes to more sustainable practices, which are increasingly important in today's environmentally conscious market.

Furthermore, the production speed of a 3 layers bubble film machine is often superior to that of traditional packaging equipment. The ability to produce large quantities of bubble film in a shorter time frame can help businesses streamline their operations, reduce labor costs, and improve overall efficiency. This increased productivity can free up resources that can be utilized in other areas of the business, such as product development or marketing.

In conclusion, incorporating a 3 layers bubble film machine into your packaging operations can provide numerous benefits, from enhanced product protection to improved efficiency and cost savings. As the demand for high-quality packaging solutions continues to grow, investing in advanced machinery like this can position your business advantageously within the competitive landscape of the packaging industry. By leveraging the unique features of 3 layers bubble film technology, you can ensure that your products reach customers in pristine condition while optimizing your operational processes.

Related News