Welcome to GuangDong Malex Machinery Technology Co.,Ltd.

Apr 14,2025

The Future of Packaging: Innovations in 3 Layers Bubble Film Machines

The Future of Packaging: Innovations in 3 Layers Bubble Film Machines

Table of Contents

- 1. Introduction to 3 Layers Bubble Film Machines

- 2. The Importance of Innovative Packaging Solutions

- 3. Understanding Bubble Film Technology

- 4. Benefits of 3 Layers Bubble Film Machines

- 4.1 Enhanced Protection Through Multi-layer Design

- 4.2 Cost Efficiency and Material Savings

- 4.3 Environmental Sustainability in Packaging

- 5. Latest Innovations in Manufacturing

- 6. Applications of 3 Layers Bubble Film Machines

- 7. Future Trends in Packaging Technology

- 8. Conclusion

- 9. FAQs

1. Introduction to 3 Layers Bubble Film Machines

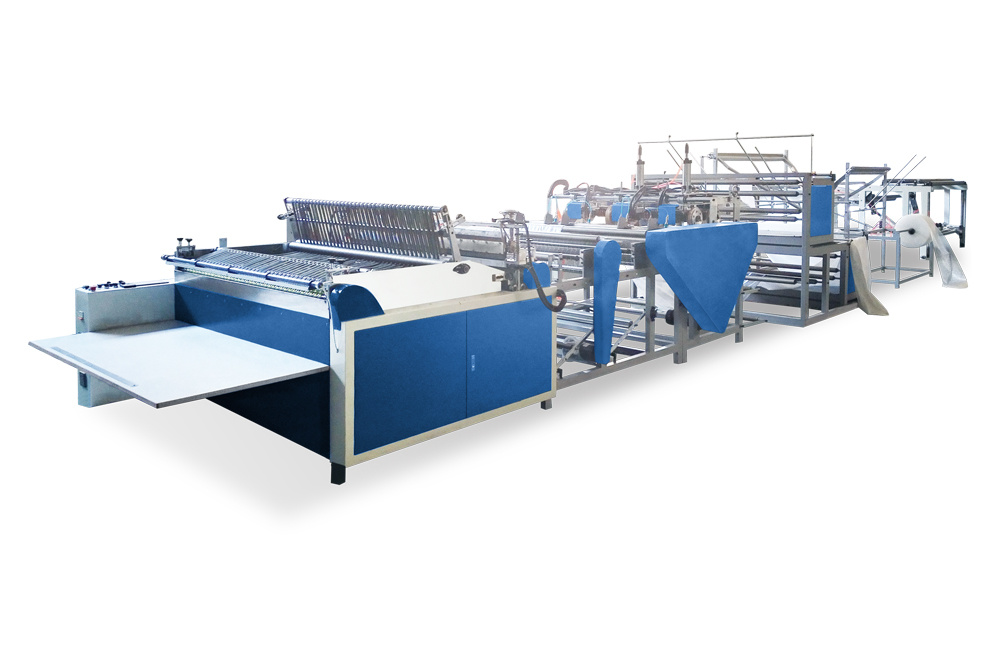

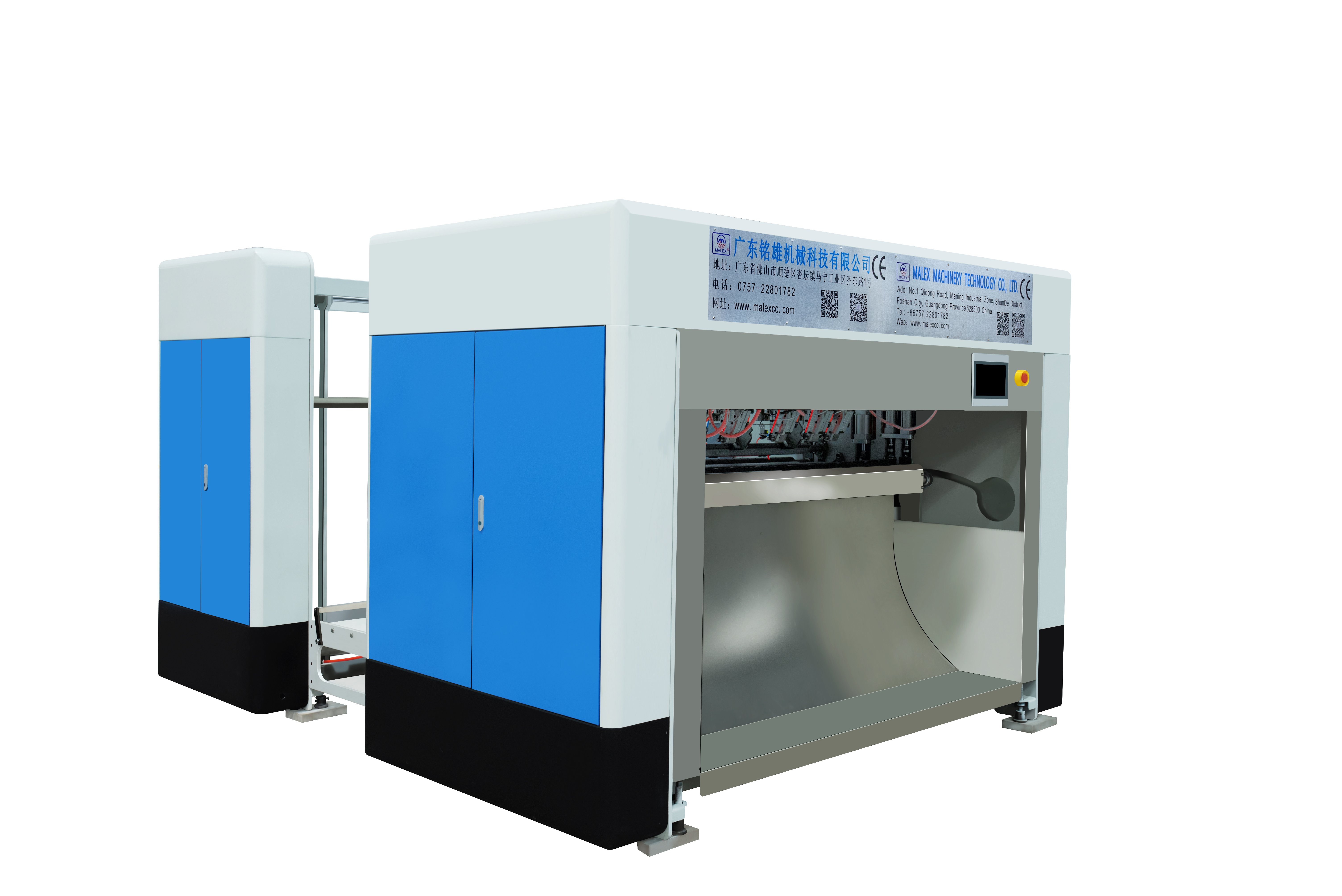

The packaging industry is undergoing a significant transformation, fueled by advancements in technology and the increasing demands of consumers and businesses alike. At the forefront of this evolution are 3 layers bubble film machines, which offer enhanced protection, cost savings, and environmental benefits. These machines create a multi-layered bubble film that is revolutionizing how products are packaged, shipped, and stored. In this article, we will delve into the innovations associated with 3 layers bubble film machines, their benefits, applications, and future trends.

2. The Importance of Innovative Packaging Solutions

In today’s fast-paced market, the significance of effective packaging cannot be overstated. Packaging serves as the first line of defense against damage during transport, ensuring products arrive safely at their destination. Moreover, it plays a crucial role in branding and consumer perception. As e-commerce continues to expand, the demand for robust and reliable packaging solutions is more critical than ever.

Innovative packaging solutions, particularly those that leverage modern technology, enhance user experience and operational efficiency. 3 layers bubble film machines exemplify this innovation by providing a flexible, protective, and lightweight packaging option that meets the evolving needs of various industries.

3. Understanding Bubble Film Technology

Bubble film technology involves the use of air-filled bubbles encased within layers of plastic. This design provides cushioning, thermal insulation, and protection against impact and vibrations. The traditional two-layer bubble film has been enhanced through the introduction of a third layer, effectively optimizing the strength and durability of the packaging while minimizing material usage.

The three layers typically consist of an outer layer for durability, a middle layer for cushioning, and an inner layer for moisture resistance. This combination not only bolsters the film's protective qualities but also extends its applicability across various sectors, including electronics, textiles, and fragile goods.

4. Benefits of 3 Layers Bubble Film Machines

The adoption of 3 layers bubble film machines comes with a multitude of advantages that cater to both manufacturers and end-users.

4.1 Enhanced Protection Through Multi-layer Design

The multi-layer design of 3 layers bubble film significantly increases the protective capabilities compared to traditional bubble films. The additional layer provides superior cushioning, ensuring that products withstand shocks and vibrations during transit. This is particularly beneficial for fragile items that are susceptible to damage.

4.2 Cost Efficiency and Material Savings

Cost efficiency is a prime concern for businesses. 3 layers bubble film machines utilize materials more effectively, reducing waste while maintaining strength. The lightweight nature of the packaging also contributes to lower shipping costs, as carriers often charge based on weight.

By employing a packaging solution that maximizes cost-effectiveness, companies can enhance their profit margins while delivering quality products to their customers.

4.3 Environmental Sustainability in Packaging

As sustainability becomes a focal point in business operations, the packaging industry is also adapting. 3 layers bubble film machines can utilize eco-friendly materials that minimize environmental impact. The reduced material usage in 3-layer designs contributes to decreased plastic waste, aligning with global efforts toward sustainable practices and responsible consumption.

Companies that adopt environmentally friendly packaging solutions not only meet regulatory standards but also appeal to eco-conscious consumers, enhancing their brand image.

5. Latest Innovations in Manufacturing

The landscape of packaging technology is continually evolving, with new innovations significantly influencing the manufacturing processes of 3 layers bubble film machines.

5.1 Advanced Materials Used in Production

Manufacturers are investing in research to develop advanced materials that enhance the functionality of bubble film. Innovations such as biodegradable plastics and recycled materials are gaining traction. These materials not only provide the same protective qualities as traditional plastics but also contribute to sustainability goals.

As the demand for environmentally responsible packaging grows, the development of these advanced materials will play a crucial role in shaping the future of the industry.

5.2 Automation and Technological Advancements

Automation is revolutionizing the manufacturing process of 3 layers bubble film machines. Automated systems improve production efficiency, reduce labor costs, and minimize human error. Advanced technology such as Artificial Intelligence (AI) and machine learning algorithms are being employed to optimize machine performance and predict maintenance needs, leading to reduced downtime and enhanced productivity.

These technological advancements not only streamline operations but also contribute to the overall quality and consistency of the packaging produced.

6. Applications of 3 Layers Bubble Film Machines

The versatility of 3 layers bubble film machines allows for a wide range of applications across various industries.

6.1 E-commerce Packaging Solutions

The rise of e-commerce has significantly increased the demand for reliable and efficient packaging solutions. 3 layers bubble film provides the necessary protection for products during shipping, ensuring they reach customers intact. The lightweight nature of this packaging means that it can be easily included in standard shipping, reducing costs for retailers.

Moreover, e-commerce businesses can leverage customizable bubble film to enhance their branding efforts, creating a memorable unboxing experience for consumers.

6.2 Industrial Packaging Applications

In industrial settings, packaging often requires durability and strength to withstand harsh environments. 3 layers bubble film machines cater to this need by producing robust packaging solutions for a variety of products, including machinery parts and heavy equipment. The superior cushioning offered by the multi-layer design ensures that even the heaviest and most delicate items are adequately protected during transport.

7. Future Trends in Packaging Technology

As we look ahead, several trends are poised to shape the future of packaging technology.

First, the integration of smart packaging solutions is on the rise. This technology allows for real-time tracking of products along the supply chain, ensuring transparency and accountability.

Second, increased focus on circular economy principles will drive innovations in recycling and reusability. Companies will seek to implement systems that allow for the reuse of packaging materials, reducing overall waste and promoting sustainability.

Lastly, advancements in digital printing technology are making custom packaging solutions more accessible and cost-effective. Businesses can now create personalized packaging that resonates with their target audience, enhancing customer engagement and loyalty.

8. Conclusion

The future of packaging is bright, and 3 layers bubble film machines are at the forefront of this evolution. With their enhanced protection, cost efficiency, and commitment to sustainability, these innovative machines are transforming the way products are packaged and shipped across various industries. As technology continues to advance, the possibilities for packaging solutions will expand, offering new ways to meet the demands of consumers and businesses alike. Embracing these innovations will not only improve operational efficiency but also contribute to a more sustainable future.

9. FAQs

1. What are 3 layers bubble film machines?

3 layers bubble film machines are specialized equipment that produce bubble film with three layers for enhanced protection and durability during product packaging.

2. How does bubble film technology work?

Bubble film technology involves creating air-filled bubbles encased within layers of plastic, providing cushioning and protection against impact and vibrations.

3. What are the benefits of using 3 layers bubble film machines?

The benefits include increased protection for products, cost efficiency through reduced material usage, and enhanced sustainability options.

4. Where can 3 layers bubble film be applied?

These machines are used across various industries, including e-commerce, electronics, textiles, and industrial packaging.

5. What future trends are expected in packaging technology?

Future trends include smart packaging solutions, increased focus on circular economy principles, and advancements in digital printing technology for customizable packaging.

Related News