Welcome to GuangDong Malex Machinery Technology Co.,Ltd.

Apr 11,2025

Understanding the Benefits and Functionality of 3 Layers Bubble Film Machines

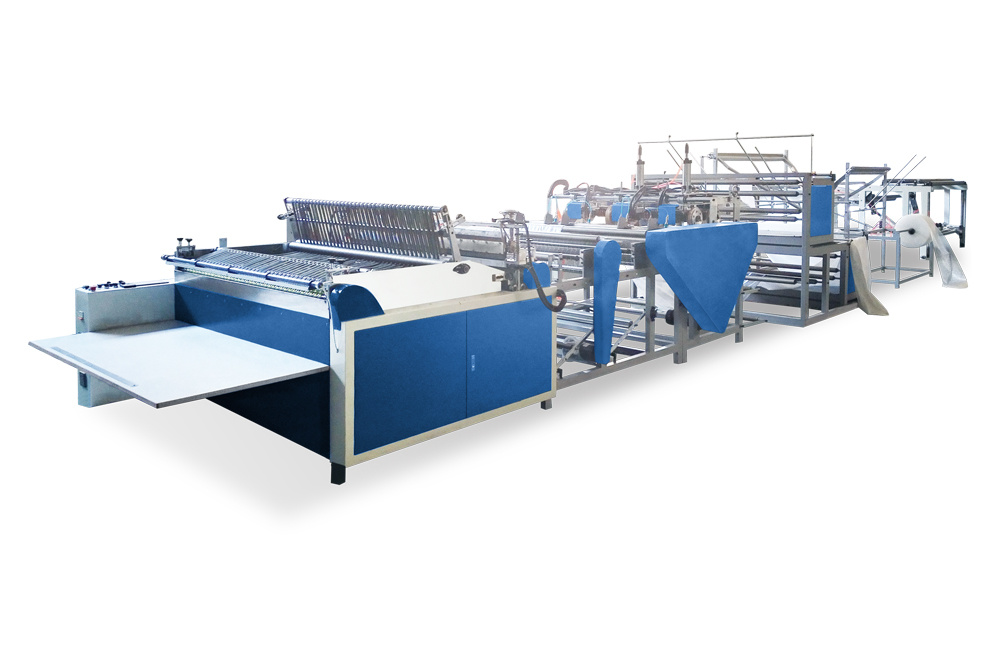

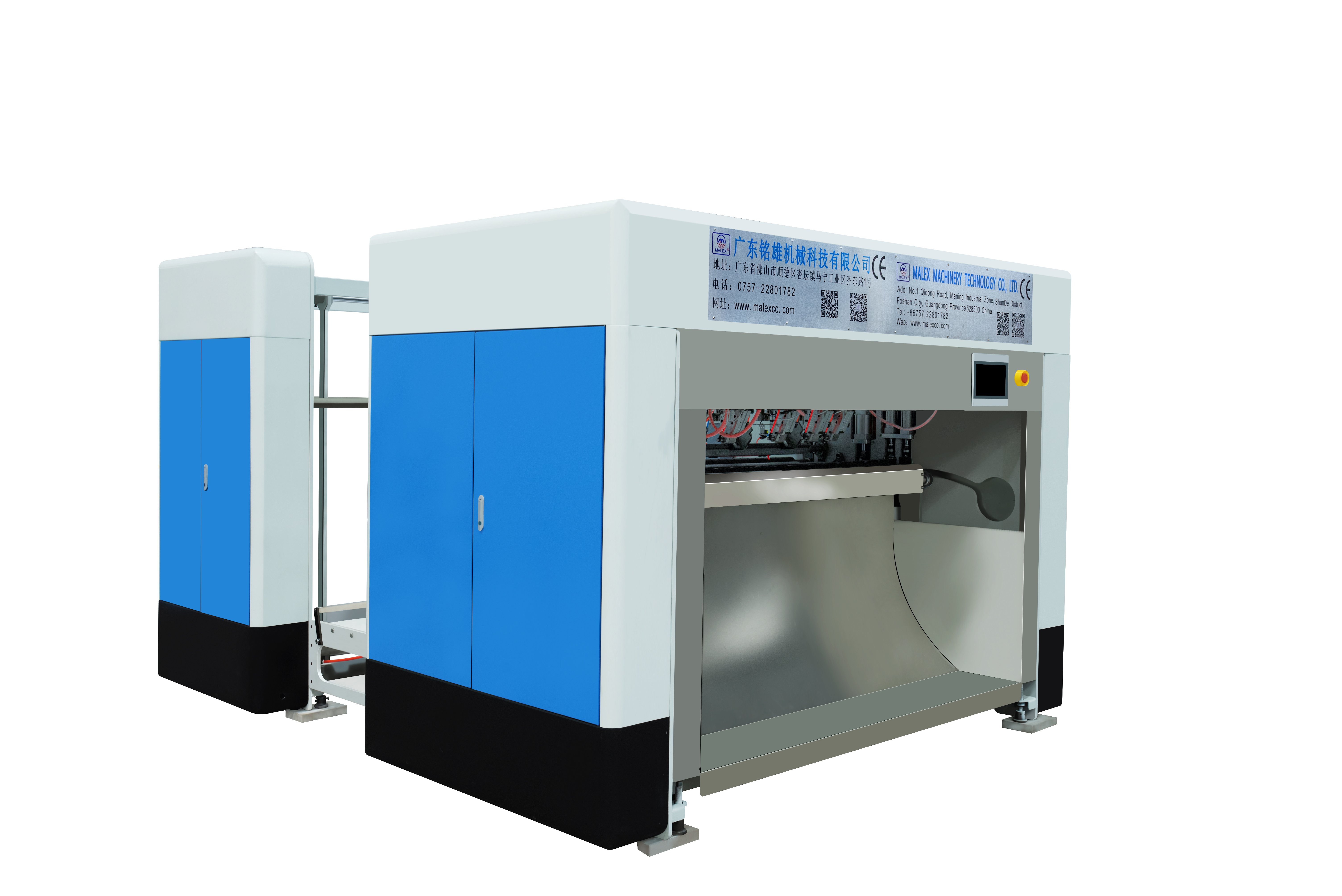

In the packaging and printing processing industry, the 3 layers bubble film machine plays a pivotal role in producing high-quality protective materials. The construction of this machine allows it to create a bubble film with three distinct layers, which significantly enhances both the durability and cushioning properties of the film.

The primary function of a 3 layers bubble film machine is to produce bubble wrap that effectively protects various products during storage and transportation. The three-layer design typically consists of two outer layers made of polyethylene and an inner layer filled with air bubbles. This configuration not only provides excellent cushioning but also ensures that the film is lightweight, making it easy to handle and transport.

One of the key advantages of using a 3 layers bubble film machine is the increased protection it offers compared to single-layer alternatives. The additional layer enhances the film's resistance to punctures and tears, which is crucial for safeguarding fragile items such as glassware, electronics, and delicate components. Furthermore, the air-filled bubbles provide effective shock absorption, reducing the likelihood of damage during transit.

In addition to enhanced protection, the 3 layers bubble film machine also contributes to increased efficiency in the packaging process. By allowing manufacturers to produce bubble film in large quantities, these machines streamline operations in factories and warehouses. This can lead to significant cost savings in terms of labor and materials, as businesses can produce their own protective packaging in-house rather than purchasing pre-made options.

Another benefit of the 3 layers bubble film machine is its versatility. The machine can be adjusted to produce various bubble sizes and thicknesses, catering to different packaging needs. This flexibility makes it suitable for a wide range of industries, from e-commerce to manufacturing, where diverse product dimensions and protection levels are required.

Moreover, the production process of a 3 layers bubble film machine is designed to be environmentally friendly. Many modern machines incorporate advanced technologies that minimize waste during production and enable the use of recyclable materials. This commitment to sustainability aligns with the growing demand for eco-friendly packaging solutions in today's market.

In summary, the 3 layers bubble film machine is an invaluable asset in the composite materials packaging industry. Its ability to produce robust and efficient protective packaging significantly enhances product safety during handling and transportation. By investing in this technology, businesses can not only improve their packaging processes but also contribute to a more sustainable future. Understanding these benefits can help professionals in the industry make informed decisions about their packaging strategies and operations.

The primary function of a 3 layers bubble film machine is to produce bubble wrap that effectively protects various products during storage and transportation. The three-layer design typically consists of two outer layers made of polyethylene and an inner layer filled with air bubbles. This configuration not only provides excellent cushioning but also ensures that the film is lightweight, making it easy to handle and transport.

One of the key advantages of using a 3 layers bubble film machine is the increased protection it offers compared to single-layer alternatives. The additional layer enhances the film's resistance to punctures and tears, which is crucial for safeguarding fragile items such as glassware, electronics, and delicate components. Furthermore, the air-filled bubbles provide effective shock absorption, reducing the likelihood of damage during transit.

In addition to enhanced protection, the 3 layers bubble film machine also contributes to increased efficiency in the packaging process. By allowing manufacturers to produce bubble film in large quantities, these machines streamline operations in factories and warehouses. This can lead to significant cost savings in terms of labor and materials, as businesses can produce their own protective packaging in-house rather than purchasing pre-made options.

Another benefit of the 3 layers bubble film machine is its versatility. The machine can be adjusted to produce various bubble sizes and thicknesses, catering to different packaging needs. This flexibility makes it suitable for a wide range of industries, from e-commerce to manufacturing, where diverse product dimensions and protection levels are required.

Moreover, the production process of a 3 layers bubble film machine is designed to be environmentally friendly. Many modern machines incorporate advanced technologies that minimize waste during production and enable the use of recyclable materials. This commitment to sustainability aligns with the growing demand for eco-friendly packaging solutions in today's market.

In summary, the 3 layers bubble film machine is an invaluable asset in the composite materials packaging industry. Its ability to produce robust and efficient protective packaging significantly enhances product safety during handling and transportation. By investing in this technology, businesses can not only improve their packaging processes but also contribute to a more sustainable future. Understanding these benefits can help professionals in the industry make informed decisions about their packaging strategies and operations.

Related News