5-Layer Air Bubble Film Machine (3-Extruder)

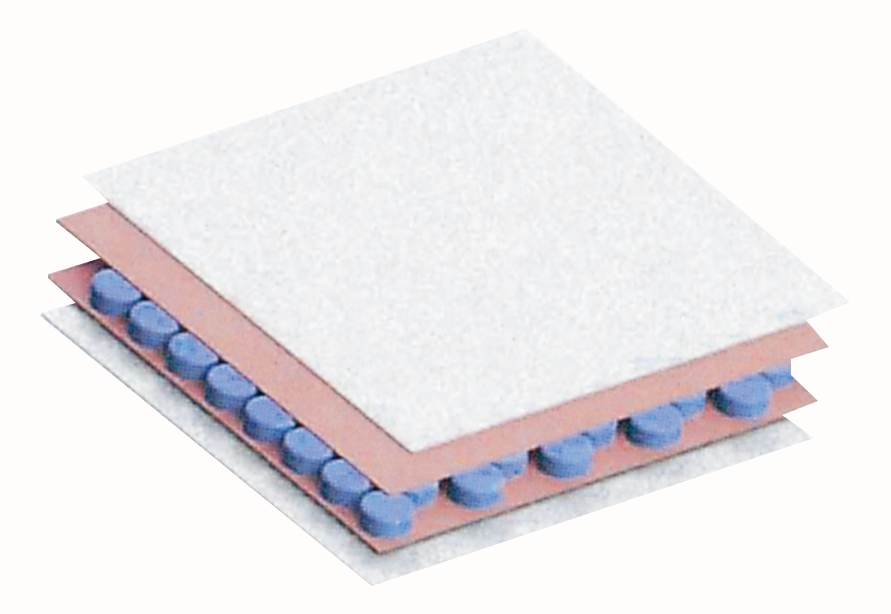

To produce 2 layers or 3 layers air bubble film (PE front layer + bubble layer +PE back layer)

And laminated 2 layers PE coated material on both sides. (it can be MPET foil, aluminum foil, kraft paper, EPE foam, PE film etc.)

Each layer is under separately controlled, can have different thickness, material formula and color.

Film Width: 1000mm~3000mm

Main Parts: extruder, forming part, winder, control panel

Speed: standard model 38m/min, customized model 60m/min.

Auxiliary Device: mixer, chiller, in-line edge trimmed recycle unit

Categories:

Keyword:

5-Layer Air Bubble Film Machine (3-Extruder)

Phone:

Email:

Enquire Now

PRODUCT DESCRIPTION

Technical Parameter

Model | MX-W100FA | MX-W160FA | MX-W200FA | MX-W300FA |

Applicable material | LDPE / LLDPE / 100% recycled material | |||

Film width | 1000mm | 1600mm | 2000mm | 3000mm |

Screw diameter | Φ65mm/Φ55mm/Φ55mm | Φ75mm/Φ65mm/Φ55mm | Φ85mm/Φ75mm/Φ65mm | Φ95mm/Φ85mm/Φ80mm |

Main motor power | 22KW/15KW/15KW | 30KW/22KW/15KW | 37KW/30KW/22KW | 45KW/37KW/30KW |

Output | 140kg/H | 180kg/H | 240kg/H | 280kg/H |

Line speed | 30m/min | 30m/min | 30m/min | 22m/min |

Product Benefits

High-efficiency & energy saving

Inverter operation, low noise, fast feedback

Customize machine

Meet special production workshop, optimized operation space

Automation and Intelligence

Paper-core auto loading, free of adhesive tape, bubble roller auto unloading etc.

Double Screw Extruder

Product performance functional, Higher output, Lower production cost

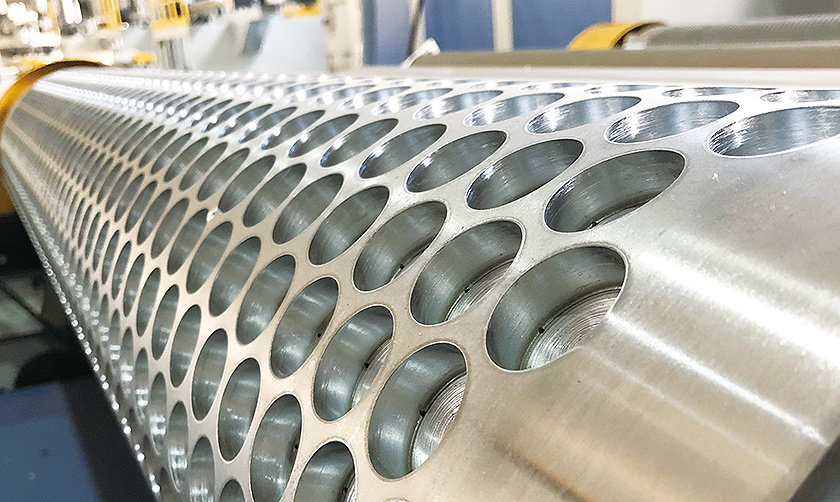

Water-cooled bubble forming cylinder

The 3rd generation bubble forming cylinder with inner water-cooled design, customized cooling with spiral design, fast cooling speed, uniform surface heat dissipation

Vacuum pump with inverter operation

Adopts inverter to adjust vacuum pump suctioned capacity, fuller air suctioned in each bubble, and lower noise.

Automatic cutting winder

The pioneer of free adhesive tape & free paper core, adopts constant tension with inverter control, winding tension is stable, reduce stretching deformation of material, reduce scrap rate, and improve the subsequent production yield.

Double servo of EPC, high precision, stable & reliable. Tension pressure transducer, it can effectively reduce the tensile deformation during co-extrusion film lamination.

Alloy treatment screw

Independently R&D screw design, increasing the length to diameter ratio, extend plasticizing section, achieving uniform shear, effectively improving plasticizing performance, can using 100% recycled materials and improving product strength.

Multi-size bubble forming cylinder installed on machine

To meet production needs of different specifications of bubble film, multiple set bubble forming cylinder can be installed simultaneously, saves disassembly time and maintaining a clean and tidy production environment.

The 5-Layer Air Bubble Film Machine (3-Extruder) is a remarkable innovation in the field of packaging machinery.

This advanced machine is designed to produce five-layer air bubble film with the assistance of three extruders. It offers a host of benefits and capabilities that set it apart.

The multiple layers of the film produced by this machine provide exceptional protection and cushioning. The five-layer construction enhances the shock-absorbing properties, safeguarding delicate items during transit and storage.

The three extruders work in harmony to ensure a precise and consistent extrusion process. They are engineered to deliver the optimal blend of materials for each layer, resulting in a high-quality and durable film.

The 5-Layer Air Bubble Film Machine (3-Extruder) is highly productive, capable of churning out a significant amount of film in a short time. This is crucial for meeting the demands of large-scale packaging operations.

It also offers flexibility in terms of adjusting various parameters such as layer thickness, bubble size, and film width. This allows for customization to meet specific packaging requirements.

The machine is built with durability in mind. Using high-quality components and materials, it is designed to withstand continuous use and provide reliable performance over an extended period.

Furthermore, the air bubble film produced by this machine is lightweight yet highly effective. It is easy to handle and can be easily cut and shaped to fit different packaging configurations.

In the packaging industry, the 5-Layer Air Bubble Film Machine (3-Extruder) is a game-changer. It provides superior packaging solutions, ensuring the safety and integrity of products while offering efficiency and cost-effectiveness. It is a valuable asset for businesses looking to enhance their packaging processes and deliver quality products to their customers.

Introducing the 5-Layer Air Bubble Film Machine (3-Extruder)”

The 5-Layer Air Bubble Film Machine (3-Extruder) is a remarkable piece of equipment that plays a crucial role in the packaging industry. This advanced machine is designed to produce high-quality air bubble film with exceptional efficiency and performance.

The key feature of this machine is its three-extruder configuration, which enables it to create a five-layer air bubble film. This multi-layer design offers enhanced strength, durability, and insulation properties. The extruders work in harmony to precisely blend and extrude the raw materials, resulting in a uniform and consistent film.

The machine is capable of handling a wide range of materials, ensuring flexibility in production. It can produce air bubble film with different bubble sizes and densities to meet the diverse needs of customers. The produced film is highly resistant to impact, shock, and abrasion, providing excellent protection for various items during transportation and storage.

With its advanced control system, the 5-Layer Air Bubble Film Machine (3-Extruder) offers precise control over various parameters such as temperature, speed, and film thickness. This allows for customizable production settings to achieve the desired film quality and characteristics.

In terms of productivity, this machine is highly efficient. It can operate at a fast pace, continuously producing large quantities of air bubble film in a short time. This helps manufacturers meet the growing demands of the market and increase their output.

The machine is also designed with user-friendliness in mind. It is easy to operate and maintain, minimizing downtime and maximizing productivity. Its reliable and stable performance ensures consistent results, reducing the risk of defects or quality issues.

Moreover, the 5-Layer Air Bubble Film Machine (3-Extruder) is built to last. It is made from high-quality components and materials, ensuring durability and long service life. This makes it a valuable investment for packaging companies looking to enhance their production capabilities and product quality.

In conclusion, the 5-Layer Air Bubble Film Machine (3-Extruder) is a state-of-the-art solution for the production of air bubble film. Its advanced features, high efficiency, and quality output make it an essential equipment for the packaging industry, enabling businesses to provide superior protection and packaging solutions for their products.

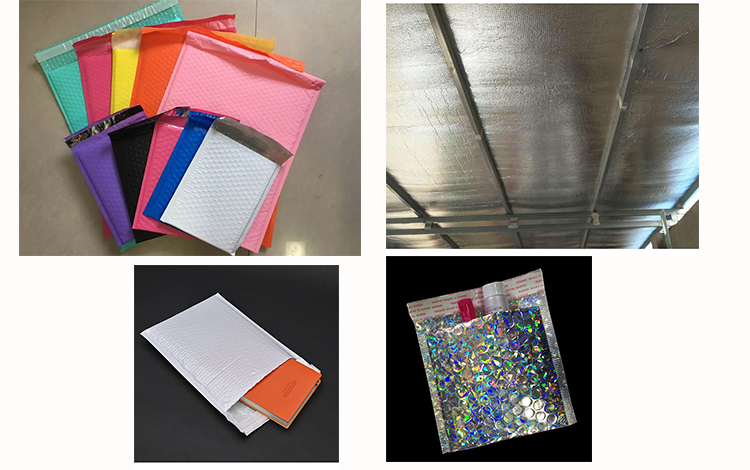

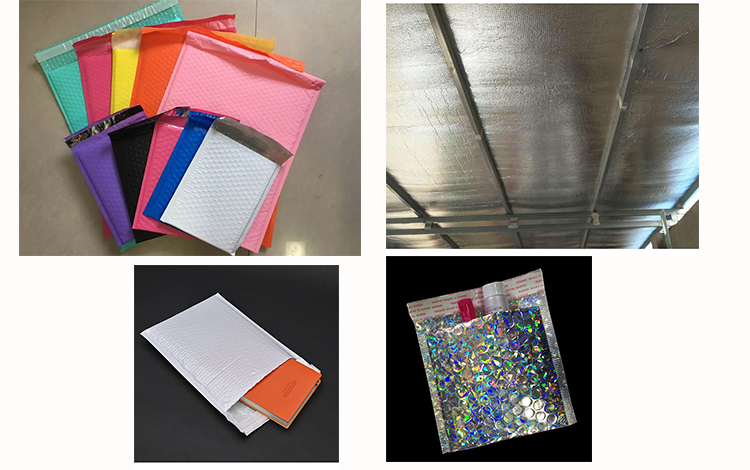

Industrial Application

Layer 5 applications

Layer 5 applications

Layer 5/7 applications

Layer 5 applications

Layer 3 applications

Layer 2 applications

Service Process

01

Requirements Analysis

Raw materials; Product performance & specification analysis

02

Equipment Selection Suggestion

Customized intelligent device; Customized specification, customized mold size

03

Whole Plant Planning Advice

Arrangements for operation, machine & material; Water, power & air requirements during operation

04

Delivery

Professional installation & tuning. On-site operation training, Regular maintenance guide

05

After Sales Service

On-site maintenance upkeep; Subsequent equipment upgrade service.

WORKSHOP VIDEO

COOPERATIVE PARTNER

APPLICATION CASES

More Products

RECOMMENDED PRODUCTS

WHY CHOOSE US

Our Advantages

Source manufacturer, Intimate service. Worry-free after-sales,

Buy with peace of mind.

YinNeng always with the corporate mission of "striving to improve the human living environment, led by senior product development experts and excellent management team, practice the corporate values of "seeking value with professionalism, seeking efficiency by management, seeking development by quality, and winning the market with innovation", It will be integrated and driven, with sanitation facilities as the main body and hardware manufacturing as the driving strategy as the development strategy, to provide customers with professional. standardized, customized and refined services.

YinNeng was established in 2019 with five years of production experience. Our team has 25 designers,10 engineers, a sales team of 28 people, 35 production managers, and more than 150 production workers. Our designer team consists of oversea designer where our deigns met oversea standards.

YinNeng with the rapid development of technology in this field, we advocate teamwork, work hard, look forward to the future of the company, and also provide a quality brand.

Welcome to visit our site

Certifications

FAQ

How flexible are you in accommodating specific design requests or modifications?

Our team have 5 designers, 6 engineer, we can deal all the customization you need.

How is the product to be delivered?

Our product can be shipped in loose component (Normal container) or in a completed unit (Flat Rack Container).

Can you provide the service of installation?

Yes, we have 80 experienced supervisors who can go to supervise the installation at any time. Meanwhile, we have a skilled installation team that can complete a number of turn-key projects.

What have you added to the value-added service?

We have camp/community planning design, indoor and outdoor electrical/plumbing design, communication/fire alarm/security system supply, furniture/electrical appliances, etc.

What is the service life and warranty period?

lifetime for capsule house is 20-50 years, container house is 15-20 years, apple cabins is 15-20 years , Mobile villa is 20-50 years. The warranty period for the whole house is 12 months from delivery.

What kind of technical drawings could you offer?

We could three-view drawing, 3d photo, blueprint, foundation, plumbing, electrical, communication, fire alarm, installation, furniture and so on.

Which certificate do you have?

We have been awarded the certificate by ce, american building code, iso9001, we have been inspected many times by tuv, sgs and bv for the factory and products.

What about the lead time?

What about the monthly quantities?

Space mobile house, Apple cabins, Mobile villa, Container house: A total of 400 units

What insulation material do you apply?

Enquire Now

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!